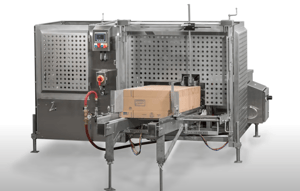

Food Safe SANITARY CONSTRUCTION Case Erector

2-EZ® SERIES

Food producers are taking an active role in assigning the highest priority to the safety and purity of their products through the entire food manufacturing process, including their end-of-line packaging.

Combi recognizes its packaging machinery's role in meat, poultry, and ready-to-eat food plants. It has stainless steel, wash-down automatic case erector bottom sealer that reduces and eliminates potential areas where undesirable bacteria might gather.

- Features

- Downloads

Features

- Cleanable - Constructed to ensure that the equipment can be effectively and efficiently cleaned and sanitized over the lifetime of the equipment, including stainless pneumatic cylinders, valves and stainless gear box with food grade lubricant

- Open Design Construction - Smooth, stainless steel materials, USDA approved, are corrosion resistant and compatible with cleaning and sanitizing chemicals. Food grade silicon vacuum cups.

- Accessible - Parts of the side belt drives are readily accessible and disassembled for inspection and cleaning without the use of tools

- Water Shedding Surfaces - Equipment covers are sloped and self-draining to assure that product, water or liquids do not accumulate or pool on the equipment surfaces

- No Hollow Areas - Limited use of threaded components and no tubing; continuous welds; stainless pointers and scales

- Hygienic Maintenance Enclosures - Stainless guarding; Nema 4x electrical and pneumatic enclosures with sloped tops and shut offs.

Case Erectors

Frequently asked questions

WHAT IS A CASE ERECTOR?

Case erectors, sometimes referred to as “box erectors,” are an automated solution that forms cases for packaging products. Combi offers a wide range of durable and reliable case erector solutions for various industries and budgets. Combi case erectors can be standalone or can integrate seamlessly with your existing packaging line.

WHAT ARE THE BENEFITS OF A COMBI CASE ERECTOR?

With a Combi case erector, you can be more efficient, save on labor and increase production. Combi case erectors give you flexibility for easy changeovers, with options for a variety of product packaging needs. We also design and engineer custom case erectors.

Combi case erectors have the strongest frame in the industry and come with a lifetime warranty. Our case erectors can also be integrated with our case packers, providing a compact solution to load products for shipping.

Contact Us

Let us put our decades of experience to work for you! Contact us today using the form below to discover how Combi can enhance your entire packaging operation, from start to finish, with advanced automation tailored to your needs.

GET IN TOUCH WITH US

WANT TO FIND OUT WHAT COMBI CAN DO FOR YOU?

Need a Quote?

REQUEST A QUOTE

Stay Connected

.png?width=161&name=ProWrap%20(1).png)